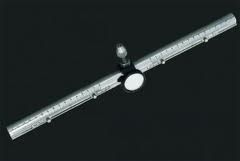

Maxwell Needle

Maxwell Needle Specification

- Temperature Range

- Room Temperature

- Feature

- Sterile, Disposable, Sharp Point

- Accuracy

- High Precision

- Model No

- Maxwell Needle

- Automation Grade

- Manual

- Core Components

- Needle Shaft, Hub

- Equipment Materials

- Stainless Steel

- Type

- Surgical Needle

- Usage

- Medical/Surgical Procedures

- Dimension (L*W*H)

- Standard

- Weight

- Lightweight

- Needle Tip Type

- Tri-beveled Sharp Tip

- Hub Color Code

- Universal Color Codes as per Gauge

- Packaging

- Individually Packed in Blister Packs

- Latex Content

- Latex Free

- Sterilization

- EO (Ethylene Oxide) Sterile

- Shelf Life

- 5 Years

- Compatibility

- Standard Luer Lock and Luer Slip Syringes

- Needle Gauge Range

- 18G to 26G

About Maxwell Needle

As a renowned name of the market, we are engaged in manufacturing and supplying Maxwell needle. This device is manufactured by our ingenious professionals using excellent quality basic materials with the help of progressive techniques. The offered device is used in physics experiments for the purpose of measuring the value of modulus of rigidity of various materials like steel wire. In addition to this, the offered Maxwell needle is made available with us in diverse specifications at rock bottom prices to our clients.

Features:

-

Easy to use

-

Less maintenance

-

High durability

-

Precise dimension

Precision Engineering for Medical Use

Maxwell Needles are crafted from high-quality stainless steel, offering sharpness and consistent performance. The tri-beveled tip promotes minimal patient discomfort and precise delivery, making these needles ideal for a wide spectrum of surgical and medical procedures. Select from 18G to 26G according to your procedural needs.

Safety and Sterility Assured

Sterilized by EO (Ethylene Oxide) and individually blister packed, Maxwell Needles ensure each instrument is completely safe for clinical use. The packaging and sterilization standards adhere strictly to medical norms, extending a secure five-year shelf life for stored or bulk-purchased inventory.

Universal Compatibility and Ease of Use

Engineered with a color-coded hub system that matches universal gauge codes, Maxwell Needles are compatible with both Luer Lock and Luer Slip syringes. Their compatibility and ergonomic design enable seamless integration in healthcare facilities and streamline clinical workflows.

FAQs of Maxwell Needle:

Q: How should Maxwell Needles be stored to maintain sterility?

A: Maxwell Needles should be stored at room temperature in their original blister packs to maintain EO sterilization. Avoid exposure to moisture or direct sunlight, and always check the packaging integrity before use to ensure sterility until the expiration date.Q: What makes the tri-beveled sharp tip of the Maxwell Needle advantageous during procedures?

A: The tri-beveled sharp tip ensures smoother and more precise penetration, which minimizes tissue trauma, reduces patient discomfort, and enhances accuracy, making it ideal for a variety of medical and surgical applications.Q: When should I choose a specific gauge size within the 18G to 26G range?

A: Gauge selection depends on the specific medical procedure and desired flow rate. Larger gauges, like 18G, are typically used for rapid fluid delivery or blood collection, whereas finer gauges, such as 26G, are suitable for delicate injections or pediatric care.Q: Where are Maxwell Needles manufactured and are they suitable for export?

A: Maxwell Needles are manufactured in India and are designed for export worldwide. Their universal specifications and high-quality construction make them suitable for healthcare systems globally.Q: What is the process of sterilization used for Maxwell Needles?

A: Each needle undergoes sterilization using Ethylene Oxide (EO) to ensure complete elimination of microbial contaminants, providing a sterile and safe product ready for medical use.Q: Can Maxwell Needles be used with any standard syringes?

A: Yes, thanks to their universal hub color coding, Maxwell Needles are compatible with both standard Luer Lock and Luer Slip syringes, offering flexibility across different clinical scenarios.Q: What benefits do Maxwell Needles offer to healthcare professionals?

A: Maxwell Needles provide high precision, reliability, and patient comfort. Their sterile packaging, compatibility with standard equipment, and latex-free construction ensure safety and efficiency in practice.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in PHYSIC RESEARCH INSTRUMENTS Category

Daniel Cell

Core Components : Copper Zinc Electrolyte solution

Type : Electrochemical cell

Equipment Materials : Copper Zinc Ceramic

Feature : Chemical energy to electrical energy conversion

Weight : Approximately 200 grams

Warranty : 1 year

Rising Table Slow Motion

Core Components : Metal base adjustable rods slowmotion mechanism

Type : Adjustment table

Equipment Materials : Metal plastic

Feature : Adjustable height slow motion functionality

Weight : Lightweight and portable

Warranty : 1 year manufacturer warranty

Post Office Boxes Brass Plugs

Core Components : Brass Plugs

Type : Post Office Boxes

Equipment Materials : Wood and Brass

Feature : Durable and Reliable

Weight : Approx. 500 grams

Warranty : 1 Year

Reading Telescope

Core Components : Lens Stand

Type : Optical Instrument

Equipment Materials : Metal and Plastic

Feature : Magnification for reading measurements

Weight : Lightweight

Warranty : 1 Year

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free